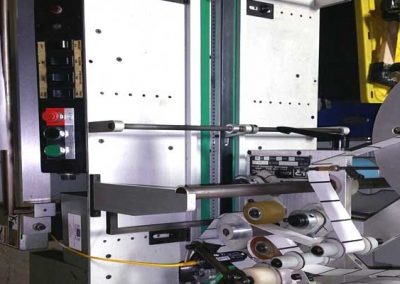

RYOBI 686 + L Offset Press

The RYOBI 686 + L Offset Press is the ideal solution for productivity and quality demanded in today’s commercial printing industry. It consistently produces high print quality at speeds of 15,000 sheets per hour and requires less operation skill, as it incorporates numerous advanced automated systems and user-friendly features.

- Manufacturer: Ryobi

- Model: 680 series

- Serial Number: 1111

- Current impression counter: 78,123,399 (as of 11/2014)

- Year: approx. 2002

- A2-Plus Size 6-Color Offset Press

- Condition: Works Good

- $145,000 obo. Ex site

- Perfector – No

- Auto Plate – Yes

- IR Dryer – Ryobi

- Blanket washers – yes, however we do manually – have all the parts…need rubber

- Coater – Anilox

- Installed new at Beard Printing 2002 (we believe that is the year of the press)

- This is a 6/c plus coating press – however one of the printing units has most of the rollers out – we use it for perfing only.

Below is a list of part that would be needed to get the 6th printing unit working for print again:

- 1 Bridge Roller + all corresponding brackets:

- # 8- Part # 91739 (x2) $74.58

- # 9- Part # 5722 48 156 (x2) $1.48

- # 10- Part # 5664 53 640 $5387.08

- # 11- Part # 5722 48 155 $2.88

- # 12- Part # 9722180008 $0.44

- # 13- Part # 5664 53 631 $312.37

- # 14- Part # 5340 53 274 $2.32

***Rubber rollers should be recovered- we have them

- Ink Key Motors

- Part # 5354 55 710 (x21) need 21 $350.00 For rebuilt or $915.70 for new

Questions asked by other sellers:

- Does it have Presets for paper size and impression pressure? No, but this is a very good feature to have.

- I see you have blanket washers you are not currently using, does it have auto impression cylinder or auto ink roller washers? No impression washers, but it does have roller wash.

- Looking at your console I can not exactly tell if you have any of the ink density control systems Ryobi offered with the press. Does the press have one of these features? Ryobi PDS Print Density control system or PDS-E Auto or PDS-E. One of these has density sensors in the press the other uses a densitometer. Maybe a scanning densitometer? We have a scanning densitometer, you must make the moves, it’s not automatic.

- Do you use prepress data to set the ink keys, CIP4? No, but the previous owner used CIP data on this press.

- Do you have the Ink Volume setter software? Yes

- Do you have a plate punch for the press. Ryobi made a pretty high tech unit do you have one? Yes, it is nice, it has occulars

- Does it have speed of 15,000 sheets? Yes, see Ryobi 680 Full Speed – on YouTube. Our pressman uploaded a video. CLICK HERE TO WATCH

- What is the configuration of IR bulbs and air knives in the delivery? 4 IR bulbs, 2 HAK’s, Air Curtain & Pre-heater

- The press has two dampening system options, one standard Ryobi-matic and the other is probably a variable speed for hickey removal. This press has standard, no variable.

- What do you use to store and pump liquid coating? We store it in drums & pump it to the press. We have a MMT Coating Unit, with ARO Pumps.

- Were there any repairs to the impression cylinders? Yes, Unit 3 has been repaired. It does not show on the print work.

Loading